Commercial Condenser Coil Cleaning

Commercial Refrigeration Condenser Coil Cleaning Boston: Protect Your Coolers, Cut Your Energy Bills

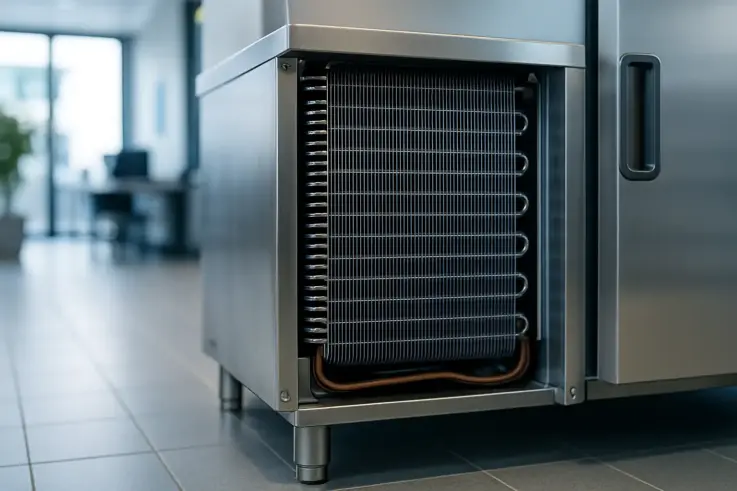

If you own or manage a restaurant, cafe, lab, market, or hotel in Massachusetts, your walk-ins and reach-ins are the heart of your business. But there’s one small part that quietly makes or breaks your entire system: the commercial refrigeration condenser coil. Regular commercial refrigeration condenser coil cleaning Boston is one of the fastest ways to reduce energy costs, avoid emergency breakdowns, and keep product safe.

In this guide, Royal Cooling’s commercial refrigeration experts break down why condenser coil cleaning matters, how often you really need it in Greater Boston, and what a professional coil service should include.

Why Dirty Condenser Coils Are a Big Problem in Greater Boston Kitchens

Condenser coils are where your refrigeration system dumps heat. When they’re coated with grease, dust, flour, or city grime, heat can’t escape efficiently. Industry data and HVAC best practices show that dirty coils:

- Increase compressor run time and electrical use

- Drive up utility bills and strain your equipment

- Cause warmer case or walk-in temperatures and product loss

- Lead to nuisance alarms and emergency no-cooling calls

- Shorten compressor life and increase repair costs

For busy foodservice operations in Boston, Cambridge, and Waltham, airborne grease, salt air, and heavy foot traffic create the perfect storm for rapid coil fouling. That’s why proactive condenser coil maintenance Waltham and across Greater Boston is not optional—it’s essential.

Key Benefits of Commercial Refrigeration Condenser Coil Cleaning Boston

1. Lower Energy Use and Utility Costs

Dirty coils force the system to work harder and run hotter. That translates directly into higher kWh consumption and higher bills. Targeted cleaning focused on dirty coils energy efficiency Cambridge can:

- Improve heat transfer and reduce compressor run time

- Lower head pressures, cutting electrical demand

- Stabilize case temperatures for better food safety

The U.S. Department of Energy and utility efficiency programs consistently highlight coil cleaning as a low-cost, high-impact maintenance task for refrigeration and HVAC systems.

2. Fewer Breakdowns and Emergency Calls

Excessive head pressure from dirty coils is one of the most common root causes of compressor failure. Regular refrigeration coil cleaning services MA are one of the best ways to prevent refrigeration system failure Boston, especially in peak summer and holiday seasons.

When Royal Cooling cleans your coils, we also check fan operation, refrigerant lines, and electrical connections—so small issues are caught before they become full-blown emergencies.

3. Longer Equipment Life and Better ROI

Every hour your system runs hotter than it should chips away at its expected lifespan. By keeping coils clean and airflow unrestricted, you:

- Reduce mechanical stress on compressors and fan motors

- Delay major capital replacement for walk-ins and line coolers

- Protect your original installation investment

4. Better Temperature Control and Food Safety

Health inspectors in Massachusetts are increasingly focused on consistent holding temperatures in walk-in coolers, freezers, and prep tables. A neglected condenser coil makes it much harder to maintain safe temperatures on hot, humid Boston days.

Clean coils support:

- Stable temperatures across cases and walk-ins

- Reduced risk of product spoilage and foodborne illness

- Easier compliance with local health department checks

How Often Should Coils Be Cleaned in Massachusetts?

There’s no one-size-fits-all answer, but as a rule of thumb for commercial cooler coil inspection Greater Boston locations:

- Heavy grease or flour environments (restaurants, bakeries, pizza, fast casual): at least every 3 months

- Medium-load environments (supermarkets, hotels, schools): every 3–6 months

- Low-load environments (offices, some labs): every 6–12 months

In Boston and Cambridge, street dust, construction debris, and salt tracked in from winter sidewalks often mean more frequent service is smart—even in relatively “clean” spaces.

Royal Cooling can help you set a custom schedule with our commercial refrigeration preventive maintenance plans in Cambridge and Greater Boston tailored to your equipment, hours, and environment.

What a Professional Refrigeration Coil Cleaning Should Include

True refrigeration coil cleaning services MA go beyond a quick vacuum. A thorough visit from Royal Cooling typically includes:

1. System and Site Assessment

- Identify all condensers: rooftop units, remote condensing units, and self-contained cases

- Review recent performance issues or alarms

- Check surrounding airflow, obstructions, and grease sources

2. Commercial Cooler Coil Inspection Greater Boston Businesses Can Rely On

- Visual inspection of fin condition and coil surfaces

- Check fan guards, fan blades, and fan motors

- Inspect electrical disconnects and wiring at each condensing unit

3. Safe, Methodical Coil Cleaning

- Remove debris, cardboard, and obstructions restricting airflow

- Pre-rinse or brush loose dirt and lint buildup

- Apply industry-approved coil cleaning solutions compatible with your equipment

- Rinse and flush from the clean side out to avoid driving dirt deeper

- Straighten bent fins where practical to restore airflow

4. Performance Check and Documentation

- Verify condenser fan operation and rotation

- Confirm head pressure and system operation trends before and after cleaning

- Document findings and recommend any repairs or further diagnostics

For a deeper checklist on keeping your system reliable, review our commercial refrigeration maintenance checklist for Cambridge businesses.

DIY vs. Professional Coil Cleaning in Boston

Your staff can help with simple housekeeping—like keeping cardboard, boxes, and trash away from outdoor or backroom condensers. But there are clear advantages to hiring professionals for full commercial refrigeration condenser coil cleaning Boston:

- Access and safety: Rooftop units, tight back-of-house spaces, and electrical disconnects require trained technicians.

- Correct chemicals: The wrong cleaner can corrode fins and shorten coil life.

- System knowledge: A trained refrigeration tech can spot early signs of failures during cleaning.

- Compliance: EPA-certified techs help ensure refrigerant, electrical, and safety standards are met.

Royal Cooling’s technicians are commercial refrigeration specialists, not general cleaners. When we clean coils, we’re also protecting your compressors, cases, and walk-ins—and your product.

How Coil Cleaning Fits into a Complete Maintenance Strategy

Condenser coil cleaning is one piece of a bigger reliability and energy strategy. To truly prevent refrigeration system failure Boston and across Massachusetts, pair coil cleaning with:

- Regular door gasket inspection and replacement

- Evaporator coil and drain pan cleaning

- Smart monitoring for temperature and alarms

- Refrigerant leak detection and corrections

Explore our detailed guidance in: